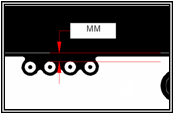

In the FPC (flexible printed circuit), we will provide a wide range of products, FPC flexible circuit switch series GOOYU offers a variety of space choice, and contains a variety of functions, can meet various application and use of the space of all market demand, and strong waterproof performance, and good impedance, very suitable for compact packaging applications.

The Gooyu FPC connector provides push and flip drives that have been pre equipped with lids to secure the connections between the FPC and connector terminals. GOOYU is developing smaller, more compact models to meet the needs of electronic equipment manufacturers for leaner sizes.

The flexible PCB board is designed to meet the requirements of a high performance internal connection, using a variety

of combinations of materials to achieve the product's use requirements

Project

Category

Conventional ability

General ability

Plate size

Min (Pcs Size)

5 ×5 mm

Max (Pcs Size)

238*440mm

Max (Pnl Size)

250*450mm

Substrate thickness

Min

0.05 mm

Max

2.0 mm

Thickness tolerance of finished products

Plate thickness < 0.5mm & nbsp; (including FR4 reinforcement, steel sheet reinforcement)

±0.050 mm

0.5mm < plate thickness & nbsp; (FR4 reinforcement, steel sheet reinforcement)

±10%

0.30mm < plate thickness & nbsp;(PI Reinforcement)

±0.020 mm

0.30mm ≤ plate thickness <0.5mm & nbsp;(PI Reinforcement)

±0.030 mm

0.5mm < plate thickness & nbsp; (PI Reinforcement)

±10%

Bottom copper thickness

Min

1/3OZ

Max

2OZ

Copper Thickness of PTH Hole Wall

N/A

1-35μm

Copper Thickness Tolerance of Controllable Hole Wall

N/A

±3 μm

TP value of copper plating

N/A

180-200%

Ratio of Longitudinal to Transverse Filling Capacity of Blind Hole (Aperture: Depth of Hole)

N/A

1.5-2.5

Blind hole filling capacity (aperture size)

N/A

50-150μm

Thickness of FPC Insulation Layer

Min

8 μm(PI thickness)

Max

90 μm(PI厚50μm,AD 厚40μm)

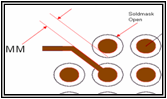

Glue overflow of covering film

BGA Special Covering Film

<0.1 mm

Common Covering Film

<0.15 mm

peel strength

base material

0.70 kgf/cm

Covering film

0.65 kgf/cm

PI/FR4 reinforcement

1.0kgf/cm

Reinforcement of steel sheet/aluminium sheet

1.0 kgf/cm

Single line impedance tolerance

N/A

±10%

Differential impedance tolerance

N/A

±10%

Minimum Linewidth Line Spacing (Double Panel)

Surface copper thickness:8-14μm

45/45 um

Surface copper thickness:15-20μm

50/50 um

Surface copper thickness:21-30μm

55/55 um

Surface copper thickness:31-40μm

75/75 um

Surface copper thickness:≥40μm

80/80 um

Line width tolerance

Linewidth ≤0.070mm

-0.02mm

0.07mm<line width≤0.15mm

±20%

Linewidth>0.10mm

±10%

Solder resist

Minimum Width/Spacing of Screen Printed Characters

N/A

5/6mil

Silk screen printing

Green oil thickness range

Line thickness

10~30 μm

Relevant

Dimensional tolerance from edge of white oil line to edge of plate

N/A

±0.25 mm

Width tolerance of white oil line

Smooth place

±0.10 mm

Concave convex place

±0.20 mm

Aperture correlation

Minimum borehole diameter

Mechanical drilling

0.100 mm

Minimum punching aperture

N/A

0.50 mm

Perform aperture tolerance

Plated through hole

±0.050 mm

Non plated through hole

±0.025 mm

SLOT Aperture Tolerance

Plated through hole

L/W>2:1:

Minimum aperture: 0.60 mm

Width:±0.050mm Length :±0.125mm

Non plated through hole

L/W>2:1:

Minimum aperture: 0.60 mm

Width:±0.025mm Length :±0.1mm

Shape and size

Minimum width of shape

N/A

1.0 mm

Minimum opening size of covering film

Punching Dimensions Using Dies

0.5mm

Using borehole size

0.35mm

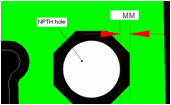

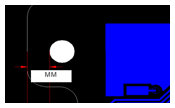

Minimum Clearance of NPTH Hole in Steel Die Punching

N/A

0.50 mm

Dimensional tolerance from hole center to hole center

Drilling hole drilling

±0.075 mm

Punching die

±0.075mm

Precision steel die punching

±0.050 mm

Circuit, PAD, Hole and Finger Center

N/A

±0.10 mm

Size tolerance to edge of plate

±0.075 mm

PITCH (span)

≤100mm

±0.05 mm

100mm<PITCH≤200mm

±0.07 mm

>200mm

±5%%

Center distance tolerance of adjacent fingers

N/A

±0.025 mm

Contour tolerance

Steel mould

±0.1mm

Precision steel mold

±0.05mm

All kinds of counterpoint ability

Alignment accuracy of covering film and reinforcement

Manual counterpoint

±0.20 mm

Alignment of jig

±0.15 mm

Automatic alignment (CCD equipment)

±0.10 mm

Alignment accuracy of electromagnetic film and glue

Manual counterpoint

±0.20 mm

Alignment of jig

±0.15 mm

Graphic alignment accuracy

Same layer

±0.05mm

Upper and lower levels

±0.05mm

Anti-welding alignment accuracy

N/A

±0.050 mm

Alignment Accuracy of Silk Printed Texts

N/A

±0.30 mm

surface treatment

Plating Ni/Au

Nickel thickness

1~ 8 μm

Thickness Tolerance of Nickel Layer

±2μm

Jin Hou

0.03 ~ 0.15 μm

Minimum spacing (golden finger or Pad)

35um

Nickel deposit

Nickel thickness

1 ~ 6 μm

Thickness Tolerance of Nickel Layer

±1μm

Jin Hou

0.03 ~ 0.075 μm

Minimum spacing (golden finger or Pad)

40um

OSP

OSP层厚

0.15~0.5μm

Expansion and contraction control capability

Controlling Tolerance of Controlling Length for Expansion and Shrinkage

Control tolerance

Control length

Cpk≥1.33

Cpk≥1.0

±0.030

≤30

≤40

±0.040

≤40

≤50

±0.050

≤50

≤70

±0.075

≤75

≤100

±0.100

≤100

≤135

±0.125

≤125

≤165

±0.150

≤150

≤200

Project

Conventional ability

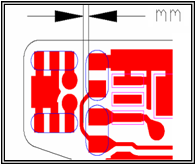

Graphic

Relevant Capacity of Line Design

Minimum Spacing between PAD and Circuit, PAD and PAD (Covering Film Process)

0.25 mm

Minimum Spacing between PAD and Circuit, PAD and PAD (Ink Process)

0.15 mm

Minimum Spacing between Parts PAD and Large Copper Skin

0.15 mm

Minimum gap (etching line) between the edge of the PAD through the hole or the line to the copper

0.03mm

Minimum Spacing between PTH Hole and PAD Edge of PTH Hole (Etching Circuit)

0.03mm

Minimum gap between AD with weld-proof window and circuit

0.13 mm

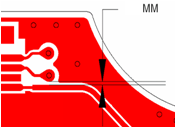

Relevant Ability of Weld Resistance Design

Minimum Width of Weld Resistance Bridge

Green oil: 0.10mm black oil: 0.15mm

Ability to design other tools

Minimum Spacing of Window Opening with Different Covering Films

0.3 mm

Minimum width of PI reinforcement

2.0 mm

Minimum Width of FR4 Reinforcement

3.0 mm

Minimum Width of Adhesive Paper/Steel Sheet Reinforcement

2.0 mm

Minimum spacing between reinforcement and electromagnetic film

0.25 mm

Minimum Spacing between NPTH Hole and Large Copper Skin

0.1 mm

The Minimum Distance Between NPTH Hole and Circuit, NPTH Hole and PAD, NPTH Hole and Board Edge

0.3 mm

Minimum spacing between NPTH holes and NPTH holes

0.5 mm

Minimum distance from element to plate edge

0.3 mm

Minimum distance from line to board edge

0.15 mm

Minimum Distance from PAD Edge of PTH Hole to Plate Edge

0.3 mm